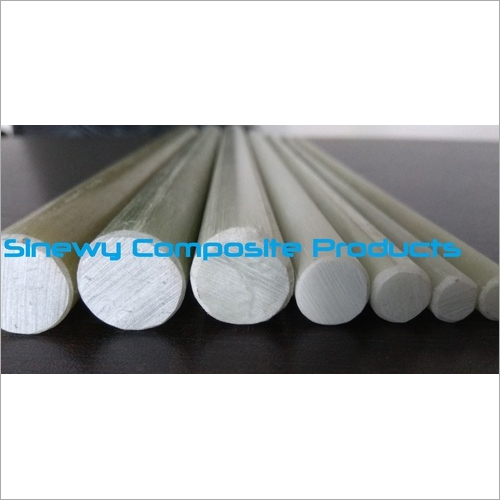

FRP ECR Insulation Rod

150.00 - 180.00 INR/Piece

Product Details:

- Usage Insulator

- Size 12 mm to 38 mm

- Material Glass Fiber Epoxy Rod

- Application Insulator for 11 kv and 66 Kv

- Technique Pultrusion process

- Product Type Insulator rod

- Surface Treatment smooth suarface

- Click to View more

X

FRP ECR Insulation Rod Price And Quantity

- 150.00 - 180.00 INR/Piece

- 100 Piece

FRP ECR Insulation Rod Product Specifications

- Insulator for 11 kv and 66 Kv

- 12 mm to 38 mm

- Insulator

- smooth suarface

- Netural greenish

- Pultrusion process

- Glass Fiber Epoxy Rod

- Insulator rod

- any

FRP ECR Insulation Rod Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 1000 Piece Per Day

- 1 Week

- Yes

- Standard Packing

- All India

- AN ISO 9001 - 2005 CERTIFIED COMPANY

Product Description

Epoxy Resin ECR fiber Glass RodEpoxy Glass Fiber rods are typically produced using a pultrusion process. In this method, continuous Glass fibers are impregnated with Epoxy Resin and then drawn through a heated die to cure. This process guarantees consistent quality and a high fiber-to-resin ratioMain features: High mechanical strength,Good electrical properties,Under dry and wet states,Flame retardant grade level UL - 94Mechanical Properties: Tensile Strength: High tensile strengthBending Strength: Measures the rods resistance to bending forces. Density: 1.60 to 2.1 kgs/cm3Electrical Properties: Dielectric Strength: voltages without breakdown. Volume Resistivity: Environmental Resistance: Water Absorption: Low water absorptionResistance to Acid and Alkali: withstand corrosive environments.FAQs of FRP ECR Insulation Rod:

Q: What sizes are available for the FRP ECR Insulation Rod?

A: The FRP ECR Insulation Rod is available in sizes ranging from 12 mm to 38 mm.Q: What material is used in the construction of the FRP ECR Insulation Rod?

A: The FRP ECR Insulation Rod is made of Glass Fiber Epoxy.Q: What is the primary technique used for manufacturing the FRP ECR Insulation Rod?

A: The FRP ECR Insulation Rod is manufactured using the pultrusion process.Q: What is the surface treatment of the FRP ECR Insulation Rod?

A: The FRP ECR Insulation Rod has a smooth surface treatment.Q: What applications can the FRP ECR Insulation Rod be used for?

A: The FRP ECR Insulation Rod is suitable for use as an insulator for 11 kV and 66 kV systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free