FRP Ladder Cable Tray

450.00 INR/Piece

Product Details:

- Usage & Applications Insulator Making

- Material Glass Fiber Epoxy Rod

- Application Insulator for 11 kv and 66 Kv

- Product Type Insulator rod

- Color white

- Click to View more

X

FRP Ladder Cable Tray Price And Quantity

- 450.00 INR/Piece

- 100 Piece

FRP Ladder Cable Tray Product Specifications

- Glass Fiber Epoxy Rod

- Insulator for 11 kv and 66 Kv

- Insulator rod

- white

- Insulator Making

FRP Ladder Cable Tray Trade Information

- 1000 Piece Per Day

- 1 Week

- No

- Standard Packing Process

- AN ISO 9001 -2015 CERTIFIED COMPANY

Product Description

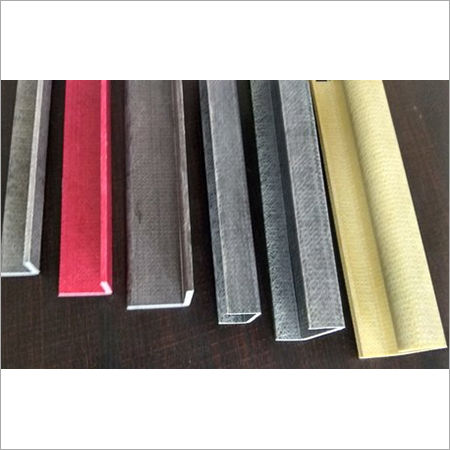

FRP Ladder Cable TrayProduct Size:Width 50-1000mm,

Height:50-150mm

Thickness: 3mm,4mm,5mm. & Customized

Length is 3 mtr and 6 mtr, and according to the customers requirements

U or C shape with standard NIMA, ASTM, GB, BIS, EN, JIS, DIN, or customers drawings

U or C shape with standard NIMA, ASTM, GB, BIS, EN, JIS, DIN, or customers drawings

" Pultrusion Process" :

The pultrusion process involves pulling raw materials through a heated die with the help of a continuous pulling device utilizing pultrusion technology.

" FRP Ladder Cable Tray:" :

Ladder cable tray systems consist of two longitudinal side members connected by individual transverse members. They are designed to support power cables or control cables.

" FRP Cable Trunking" :

FRP cable trunking is a fully enclosed cable tray system used for the installation of various cables, including telecommunications cables, thermocouple cables, and other sensitive control cables.

FRP tray type cable tray

Engineered for Insulator Making

Manufactured with precision, our FRP Ladder Cable Trays are tailored for use in the fabrication of electrical insulators, particularly for 11 kV and 66 kV applications. The robust construction using glass fiber epoxy rods ensures high dielectric strength and excellent mechanical properties, essential for safe power transmission systems.

Distinct White Finish and Material Advantages

The striking white coloration of our cable trays not only complements industrial settings but also offers enhanced visibility for maintenance and inspections. The use of glass fiber epoxy rod ensures lightweight design, formidable strength, and resistance to weathering and electrical hazards.

Trusted Indian Exporter and Supplier

Based in India, we serve a diverse customer base as an experienced exporter, manufacturer, and supplier of FRP cable management solutions. Our commitment to quality ensures that each product meets the rigorous demands of modern electrical insulator industries.

FAQs of FRP Ladder Cable Tray:

Q: How is the FRP Ladder Cable Tray utilized in the insulator making process for 11 kV and 66 kV applications?

A: The FRP Ladder Cable Tray serves as a crucial insulating component during the assembly of insulators for 11 kV and 66 kV systems. It provides structural support and maintains electrical isolation, ensuring safe and efficient power transmission during manufacturing.Q: What benefits does the glass fiber epoxy rod material offer in FRP Ladder Cable Trays?

A: Glass fiber epoxy rod imparts exceptional electrical insulation, mechanical strength, and resistance to corrosion and moisture, making it ideal for insulator manufacturing. These properties contribute to longer-lasting, safer components in power infrastructure.Q: When should FRP Ladder Cable Trays be selected over traditional metal trays for insulator making?

A: FRP Ladder Cable Trays are especially suitable when superior electrical insulation, lightweight handling, and resistance to environmental factors are required, such as in advanced insulator manufacturing for high-voltage applications.Q: Where are these FRP Ladder Cable Trays primarily manufactured and supplied from?

A: Our FRP Ladder Cable Trays are manufactured and supplied from India, catering to both domestic and global clients as a dedicated exporter, manufacturer, and supplier.Q: What is the typical process for installing FRP Ladder Cable Trays in insulator production facilities?

A: The trays are positioned to provide optimal support for insulator components, ensuring electrical separation and structural integrity. Installation is straightforward due to the lightweight nature of FRP, reducing handling time and effort.Q: Which advantages do users gain by choosing white-colored FRP Ladder Cable Trays?

A: The white color offers enhanced visibility for maintenance and inspections, while contributing to a clean, organized appearance in production environments.Q: How does the use of FRP Ladder Cable Trays enhance safety and reliability in electrical insulator applications?

A: FRP Ladder Cable Trays minimize risks of electrical faults due to their high insulation properties and resistance to environmental degradation. This results in improved reliability and reduced maintenance needs in power distribution systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS